Conference Proceedings

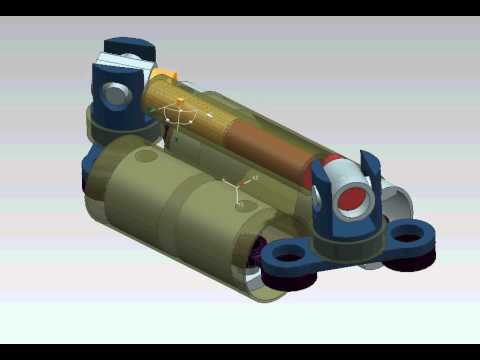

Opposed piston engines need to not be confused with flat engines , which are horizontally opposed with one particular piston per cylinder, and cylinder heads. It is also to be noted that for the duration of the later portion of the work cycle, past the point of maximum expansion, the gas is slightly compressed just before exhaust commences and this slight compression portion of the cycle of rotation, from around 45 degrees prior to bottom dead center of the principal piston to bottom dead center, permits the fuel to much more completely burn and thus, minimizes the presence of undesirable exhaust gas fumes.

Opposed piston engines need to not be confused with flat engines , which are horizontally opposed with one particular piston per cylinder, and cylinder heads. It is also to be noted that for the duration of the later portion of the work cycle, past the point of maximum expansion, the gas is slightly compressed just before exhaust commences and this slight compression portion of the cycle of rotation, from around 45 degrees prior to bottom dead center of the principal piston to bottom dead center, permits the fuel to much more completely burn and thus, minimizes the presence of undesirable exhaust gas fumes.

The benefit is clear, for an engine may well be started with the crankshafts in a position exactly where the compression ratio is, say for example, 7 to 1. Right after it is running at high speed, a phase shift can then be created where the compression …

Conference Proceedings Read More