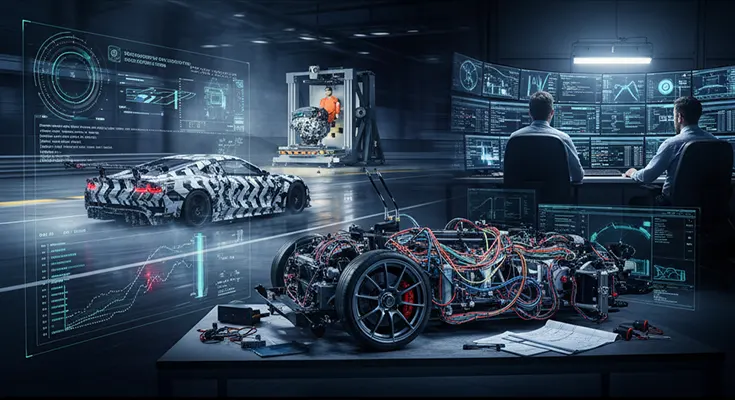

The journey from a sketch on a designer’s napkin to a gleaming, road-ready vehicle is one of the most complex engineering feats in the modern world. At the heart of this entire process, serving as both a compass and a safety net, lies the rigorous, iterative cycle of testing and prototyping. Far from being mere formalities, these stages are the crucibles where concepts are forged into reliable, safe, and marketable automobiles.

In an industry where innovation cycles are shrinking and safety standards are constantly rising, the importance of comprehensive prototyping and testing cannot be overstated. They are crucial for mitigating risk, controlling costs, and ensuring the final product meets the demands of both regulatory bodies and discerning consumers.

1. Risk Mitigation and Early Problem Detection

The primary function of prototyping and testing is to act as an early warning system. Identifying and correcting a design flaw in the digital or physical prototype phase is dramatically cheaper than discovering it after production tooling has begun or, worse, after the vehicle has been sold to customers (leading to a costly recall).

- Cost Efficiency: Each prototype iteration—from low-fidelity foam models to high-fidelity, functional “mule” cars—allows engineers to validate design concepts. Catching a structural weakness or an integration error early can save manufacturers millions in potential tooling rework and warranty claims. Studies suggest that fixing an error in the virtual prototyping stage can save 25-30% of development costs.

- Feasibility Validation: Prototypes prove whether a new technology or radical design choice (e.g., a complex electric drivetrain, a new lightweight alloy, or an innovative suspension geometry) is technically viable, manufacturable, and functional under real-world conditions.

2. Ensuring Safety and Regulatory Compliance

In the automotive world, safety is non-negotiable. Testing is the only way to ensure a vehicle protects its occupants and adheres to global safety standards.

- Crashworthiness and Safety Systems: Physical prototypes are subjected to brutal, instrumented crash tests to evaluate the structural integrity, airbag deployment, and occupant protection in various collision scenarios. Digital simulations (virtual crash testing) are used extensively to refine designs before the first physical prototype is built, ensuring compliance with standards like the NCAP and ISO 26262 (Functional Safety).

- Emissions and Durability: Prototypes undergo millions of miles of grueling durability and environmental testing—from extreme heat and cold chambers to rigorous chassis dynamometer tests—to validate long-term reliability and ensure engine and exhaust systems meet strict emissions regulations.

3. Iteration, Refinement, and Performance Optimization

Prototyping is an iterative process, not a single step. Each test yields data that feeds back into the design process, making the next version better.

- Performance Tuning: Engineers use prototypes for extensive performance testing, fine-tuning critical systems such as braking (ABS, stability control), suspension (ride comfort and handling), and powertrain calibration (power output, fuel economy, and transmission shift points).

- NVH (Noise, Vibration, and Harshness): Prototypes are essential for measuring and mitigating unwanted Noise, Vibration, and Harshness, which are critical factors in perceived vehicle quality and customer satisfaction.

4. Human-Centric Design and Usability

A car must be safe, but it must also be intuitive and comfortable for the driver and passengers.

- Ergonomics and User Experience (UX): Prototypes—especially “buck” or cockpit prototypes—allow design teams to test the usability of the infotainment system, the comfort of the seats, the placement of controls, and the overall driver sightlines before committing to expensive tooling. This ensures the final vehicle is comfortable and simple to operate, reducing driver distraction.

- Market Readiness: Early prototypes are often shown to focus groups to gather feedback on aesthetics, features, and functionality, ensuring the car aligns with customer expectations before its official launch.

Testing and prototyping are the bedrock of the automotive development process. They transition an abstract vision into a tangible product by providing an essential bridge between conceptual design and mass production. Through a continuous loop of virtual simulation, physical construction, and rigorous validation, manufacturers not only catch and correct costly flaws but also unlock the potential for truly innovative, high-performing, and, most importantly, safe vehicles. In the high-stakes world of car manufacturing, the prototype is not just a model—it is the guarantee of quality, reliability, and market success.