Chroming It Up: Car Parts

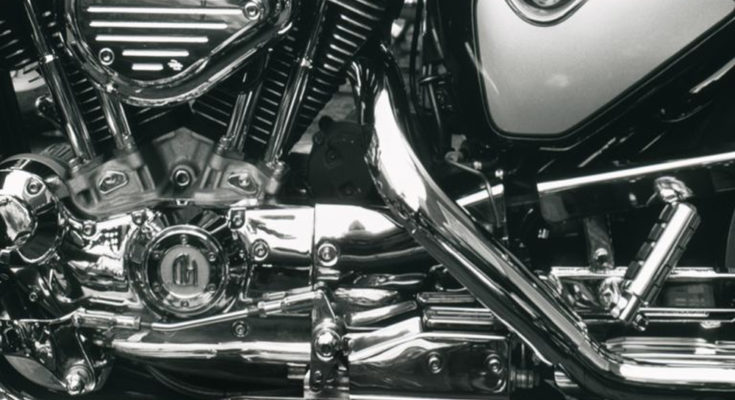

Chrome, short for chromium element, is used in many industries ranging from kitchen accessories to clothing fabrics to furniture decoration. The biggest chrome user in the automotive industry. Trims, accessories, and under hoods are all covered with chrome for a bright and shiny appearance.

Chrome must be applied through the electroplating process while the basic application of chrome will receive a negative charge and be “immersed” in a chromium tub that is positively charged. This concept is very similar to electrostatic spray paintings used on car bodies except in place of sprays, the item is dipped. After this process is complete, chrome is almost indestructible and is impossible to remove.

Chrome Can Be Used On Almost All Surfaces

One of the biggest attractions for using chrome in the car industry besides its slim result is that it can be used on almost all surfaces, including copper, iron and other metal …

Chroming It Up: Car Parts Read More