Project Gutenberg Self

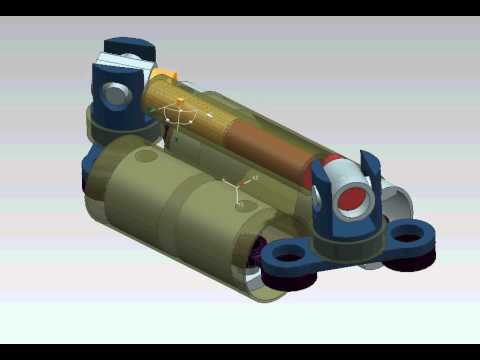

The initially diesel engine with opposed pistons, was a prototype constructed at the Kolomna plant in Russia. A major object of the invention is to present an novel and enhanced opposed piston engine, wherein the rotation of 1 crankshaft is phased to lag the rotation of the other by approximately 90 degrees to improve the operative, cyclic action of the prime mover gas inside the cylinder chambers between the pistons and to an enhanced sustained torque output with a substantial reduction in vibration creating effects.

The initially diesel engine with opposed pistons, was a prototype constructed at the Kolomna plant in Russia. A major object of the invention is to present an novel and enhanced opposed piston engine, wherein the rotation of 1 crankshaft is phased to lag the rotation of the other by approximately 90 degrees to improve the operative, cyclic action of the prime mover gas inside the cylinder chambers between the pistons and to an enhanced sustained torque output with a substantial reduction in vibration creating effects.

The larger the initial combustion pressure worth and the reduce the exhausted temperature and pressure values the more highly effective and effective your engine is. regardless of geometry or architecture of engine. Koreyvo, Jumo and Napier Deltic engines applied a single piston per cylinder to expose an intake port, and the other to expose an exhaust port. Why can a piston take compression ratios of …

Project Gutenberg Self Read More

There are some subjects a single desires to realize technically to create about, and engines are 1 of them. It is so produced so that it can offer high torque for the car or truck to carry additional load or move uphill easily. An additional element that is in each and every vehicle at present that will no longer be necessary in an electric vehicle is the alternator that powers the electrical systems of a combustion engine car or truck. In fact, the energy generated from an electric motor is much larger and continual compared to an internal combustion engine. The V-sort of engine has two rows of cylinders set usually at a ninety degree angle to each and every other.

There are some subjects a single desires to realize technically to create about, and engines are 1 of them. It is so produced so that it can offer high torque for the car or truck to carry additional load or move uphill easily. An additional element that is in each and every vehicle at present that will no longer be necessary in an electric vehicle is the alternator that powers the electrical systems of a combustion engine car or truck. In fact, the energy generated from an electric motor is much larger and continual compared to an internal combustion engine. The V-sort of engine has two rows of cylinders set usually at a ninety degree angle to each and every other. Opposed piston engines need to not be confused with flat engines , which are horizontally opposed with one particular piston per cylinder, and cylinder heads. It is also to be noted that for the duration of the later portion of the work cycle, past the point of maximum expansion, the gas is slightly compressed just before exhaust commences and this slight compression portion of the cycle of rotation, from around 45 degrees prior to bottom dead center of the principal piston to bottom dead center, permits the fuel to much more completely burn and thus, minimizes the presence of undesirable exhaust gas fumes.

Opposed piston engines need to not be confused with flat engines , which are horizontally opposed with one particular piston per cylinder, and cylinder heads. It is also to be noted that for the duration of the later portion of the work cycle, past the point of maximum expansion, the gas is slightly compressed just before exhaust commences and this slight compression portion of the cycle of rotation, from around 45 degrees prior to bottom dead center of the principal piston to bottom dead center, permits the fuel to much more completely burn and thus, minimizes the presence of undesirable exhaust gas fumes. On April 29, 1882, the renowned electrical inventor Werner Siemens drove an electrically powered carriage or trolley bus- ‘the Elektromote’ along a Berlin test track about 550 metres lengthy, near Halensee. On the other hand, in engines that make use of compression rather than spark ignition, by indicates of quite higher compression ratios (14-25:1), such as the diesel engine or Bourke engine , higher octane fuel is not important. Improving the efficiency of internal combustion engines is one particular of the most promising and cost-powerful near- to mid-term approaches to increasing highway vehicles’ fuel economy. Higher temperature oil is much less viscous, so significantly less torque is essential for operation and the transmission and engine can operate at greater mechanical efficiencies.

On April 29, 1882, the renowned electrical inventor Werner Siemens drove an electrically powered carriage or trolley bus- ‘the Elektromote’ along a Berlin test track about 550 metres lengthy, near Halensee. On the other hand, in engines that make use of compression rather than spark ignition, by indicates of quite higher compression ratios (14-25:1), such as the diesel engine or Bourke engine , higher octane fuel is not important. Improving the efficiency of internal combustion engines is one particular of the most promising and cost-powerful near- to mid-term approaches to increasing highway vehicles’ fuel economy. Higher temperature oil is much less viscous, so significantly less torque is essential for operation and the transmission and engine can operate at greater mechanical efficiencies. A international team of automotive electrical systems consultants with substantial encounter in engineering hybrid, plug-in hybrid, electric and variety extended electric autos. The engine surfaces radiate sound which is emitted as an airborne source, at the connection points with the rest of the automobile (engine mounts, connection to driveline…) also vibration is generated and injected as a force in the rest of the car or truck, corresponding to structure borne components. Apart from the battery used for the auto mechanism, there is also an added 12 V battery on board.

A international team of automotive electrical systems consultants with substantial encounter in engineering hybrid, plug-in hybrid, electric and variety extended electric autos. The engine surfaces radiate sound which is emitted as an airborne source, at the connection points with the rest of the automobile (engine mounts, connection to driveline…) also vibration is generated and injected as a force in the rest of the car or truck, corresponding to structure borne components. Apart from the battery used for the auto mechanism, there is also an added 12 V battery on board.