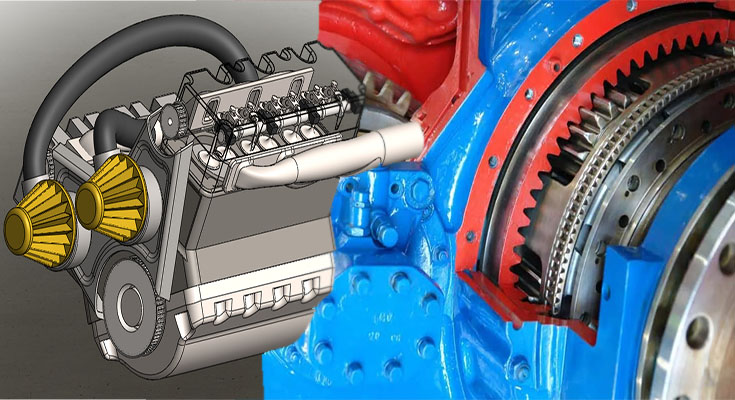

How to Create a Car Engine Design in SolidWorks

To start with a car engine design in Solidworks, you must understand what makes a piston work. Pistons have cylindrical shapes, and the process of modeling one starts with a sketch of its revolution. This sketch should be black, as it indicates that it is fully constrained. Next, you must model the connecting rod, which is symmetrical in shape. Lastly, you should consider the constraints that exist between the parts.

Flow simulation

Flow simulation for car engine design in SolidWorks can simulate many different aspects of the combustion process. The application can analyze STEP or IGES files. Simply go to Tools > Add-Ins and check the appropriate box. A simulation will begin. The software can analyze various kinds of solid geometry, including fuel-air mixtures, vapor-liquid interfaces, and fluid-solid interfaces. It can also analyze a variety of different flow phenomena, including fugitive fuel gas.

Once you’ve defined your unit system, you …

How to Create a Car Engine Design in SolidWorks Read More