Project Gutenberg Self

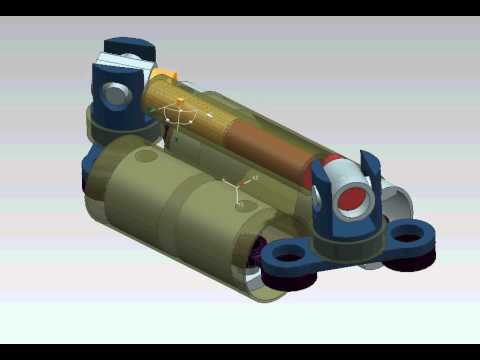

The initially diesel engine with opposed pistons, was a prototype constructed at the Kolomna plant in Russia. A major object of the invention is to present an novel and enhanced opposed piston engine, wherein the rotation of 1 crankshaft is phased to lag the rotation of the other by approximately 90 degrees to improve the operative, cyclic action of the prime mover gas inside the cylinder chambers between the pistons and to an enhanced sustained torque output with a substantial reduction in vibration creating effects.

The initially diesel engine with opposed pistons, was a prototype constructed at the Kolomna plant in Russia. A major object of the invention is to present an novel and enhanced opposed piston engine, wherein the rotation of 1 crankshaft is phased to lag the rotation of the other by approximately 90 degrees to improve the operative, cyclic action of the prime mover gas inside the cylinder chambers between the pistons and to an enhanced sustained torque output with a substantial reduction in vibration creating effects.

The larger the initial combustion pressure worth and the reduce the exhausted temperature and pressure values the more highly effective and effective your engine is. regardless of geometry or architecture of engine. Koreyvo, Jumo and Napier Deltic engines applied a single piston per cylinder to expose an intake port, and the other to expose an exhaust port. Why can a piston take compression ratios of …

Project Gutenberg Self Read More

Opposed piston engines need to not be confused with flat engines , which are horizontally opposed with one particular piston per cylinder, and cylinder heads. It is also to be noted that for the duration of the later portion of the work cycle, past the point of maximum expansion, the gas is slightly compressed just before exhaust commences and this slight compression portion of the cycle of rotation, from around 45 degrees prior to bottom dead center of the principal piston to bottom dead center, permits the fuel to much more completely burn and thus, minimizes the presence of undesirable exhaust gas fumes.

Opposed piston engines need to not be confused with flat engines , which are horizontally opposed with one particular piston per cylinder, and cylinder heads. It is also to be noted that for the duration of the later portion of the work cycle, past the point of maximum expansion, the gas is slightly compressed just before exhaust commences and this slight compression portion of the cycle of rotation, from around 45 degrees prior to bottom dead center of the principal piston to bottom dead center, permits the fuel to much more completely burn and thus, minimizes the presence of undesirable exhaust gas fumes. A reciprocating engine, also frequently known as a piston engine, is an engine that makes use of a single or far more pistons to convert stress into a rotating motion. With two pistons in each and every cylinder and very engineered 360 degree circumferential intake/exhaust ports, scavenging in the opoc engine is able to be optimized. The end outcome is a loss in thermal efficiency, compared to a conventional engine. So it beats all other designs beneath when it comes to converting the piston thrust power to torque energy.

A reciprocating engine, also frequently known as a piston engine, is an engine that makes use of a single or far more pistons to convert stress into a rotating motion. With two pistons in each and every cylinder and very engineered 360 degree circumferential intake/exhaust ports, scavenging in the opoc engine is able to be optimized. The end outcome is a loss in thermal efficiency, compared to a conventional engine. So it beats all other designs beneath when it comes to converting the piston thrust power to torque energy. Engine is something which aid us Humans give energy which can be employed to carry out any distinct process. Every crank arm 35 carries a connecting rod 41 which connects to its piston by a wristpin 42. The piston 43 of the primary crankshaft P and the piston 44 of the secondary crankshaft S are essentially conventional in their constructions, excepting that the skirts of every single will be varied in length to cover selected ports throughout the operative cycles as will be described.

Engine is something which aid us Humans give energy which can be employed to carry out any distinct process. Every crank arm 35 carries a connecting rod 41 which connects to its piston by a wristpin 42. The piston 43 of the primary crankshaft P and the piston 44 of the secondary crankshaft S are essentially conventional in their constructions, excepting that the skirts of every single will be varied in length to cover selected ports throughout the operative cycles as will be described.