The modern automotive industry is in the midst of a profound revolution. The shift is no longer just about horsepower and sheet metal; it’s about software, data, and sustainable processes. The traditional, multi-year, physical prototyping process is being rapidly replaced by agile, digital-first methodologies.

These latest innovations shaping the modern car development process are transforming vehicles into “Software-Defined Vehicles” (SDVs) and factories into intelligent, interconnected ecosystems.Here are the key trends driving the new era of automotive development.

1. The Rise of the Software-Defined Vehicle (SDV)

The most significant change is the recognition that the car is now a high-powered computing platform. This changes the focus of development from hardware to software.

- Over-the-Air (OTA) Updates: Borrowed from the consumer electronics world, OTA updates allow manufacturers to deploy new features, performance improvements, security patches, and even recalls remotely. This radically shortens the development cycle, allowing for continuous refinement even after the vehicle is sold.

- Centralized Computing Architectures: Modern cars are moving away from having dozens of separate Electronic Control Units (ECUs) to a few high-performance central computers. This simplified architecture makes software development, integration, and debugging far more efficient.

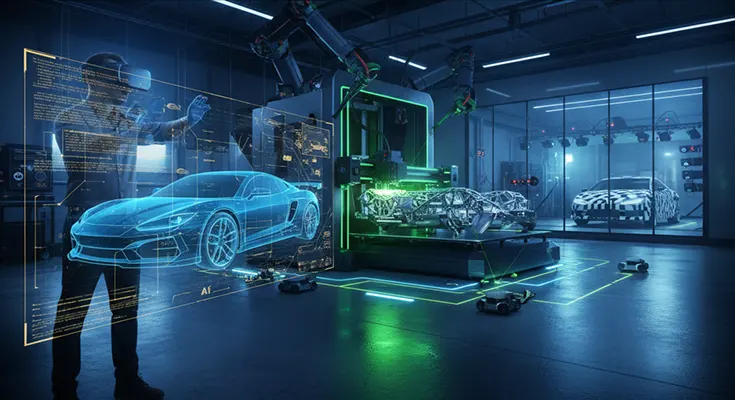

2. Digital Twins and Virtual Validation

The digital realm has become the primary testing ground, saving billions in costs and years in development time.

- The Digital Twin: A “Digital Twin” is a complete virtual replica of a car, a factory, or even an entire production line. Engineers can simulate every conceivable scenario—from crash tests and aerodynamic performance to thermal management and manufacturing tolerances—before a single physical part is created. This accelerates the process of design iteration and failure prediction.

- Virtual and Augmented Reality (VR/AR): VR and AR tools are now used extensively in the design studio and on the assembly line. Designers can step into a virtual mock-up of an interior, and engineers can collaboratively inspect complex 3D prototypes from opposite sides of the globe, improving teamwork and reducing the need for costly physical travel and mock-ups.

3. Artificial Intelligence (AI) in Design and Manufacturing

AI and Machine Learning (ML) are being integrated throughout the value chain, leading to unprecedented levels of efficiency and safety.

- Generative Design: AI algorithms can explore thousands of design options based on constraints like weight, strength, and material properties. This process often yields novel, lightweight, and highly efficient component designs that human engineers might not have considered.

- Predictive Maintenance in the Factory: AI-powered sensors monitor manufacturing equipment in real time. They can predict when a machine is likely to fail, allowing for pre-emptive maintenance.This dramatically reduces costly downtime and ensures consistent quality.

- Advanced Driver-Assistance Systems (ADAS) Development: AI is the core technology behind features like automated emergency braking and lane-keeping assist. The development process now heavily relies on feeding vast amounts of real-world and simulated data to train sophisticated ML models, rapidly pushing toward higher levels of autonomy.

4. Electrification and Sustainable Materials

The pivot to Electric Vehicles (EVs) is fundamentally restructuring the development process, demanding new expertise and material science breakthroughs.

- Battery Innovation Focus: A significant portion of R&D is dedicated to developing more energy-dense, faster-charging, and safer battery technologies (such as solid-state batteries). This requires new processes for thermal management, packaging, and recycling within the vehicle structure.

- Lightweighting and CleanTech: To maximize EV range, manufacturers are accelerating the use of advanced, lightweight materials like carbon fiber composites and high-strength aluminum alloys. Furthermore, the development process prioritizes sustainable manufacturing methods, focusing on using recycled and bio-based materials to reduce the vehicle’s overall carbon footprint.

5. Hyper-Connectivity and Data Analytics

Modern cars are constantly connected to the cloud, generating a massive stream of “Big Data” that feeds directly back into the development loop.

- Vehicle-to-Everything (V2X) Communication: New development efforts focus on building V2X capabilities, allowing vehicles to talk to each other ($V2V$), to the road infrastructure ($V2I$), and to pedestrians.This level of connectivity is essential for the next generation of safety and traffic management systems.

- Closed-Loop Feedback: Real-world data on driving patterns, component performance, and feature usage is collected and fed back to the engineering teams. This predictive maintenance intelligence allows engineers to diagnose and correct issues in future models before they become widespread problems, creating a fast, continuous loop of improvement.

The modern car development process is less like traditional manufacturing and more like high-speed software development. By embracing connectivity, AI, and digital simulation, manufacturers are not just building better cars; they are fundamentally redefining what a car is: a constantly evolving, connected mobility platform designed and perfected in a state-of-the-art digital environment.