Fueling Success: Electronic Fuel Injection System Maintenance Tips for Beginners

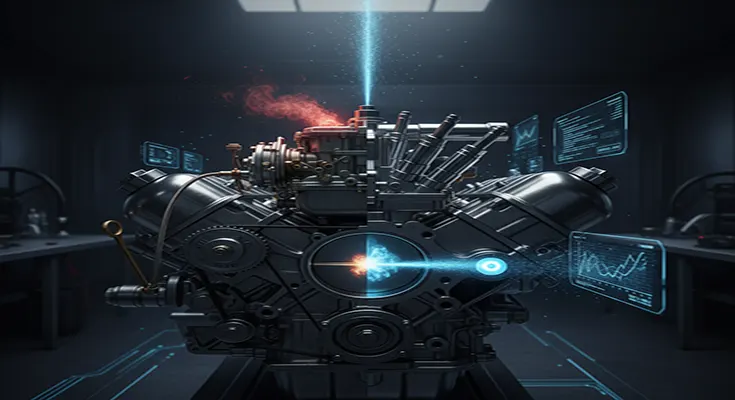

Modern vehicles owe their efficiency, smooth performance, and low emissions largely to the Electronic Fuel Injection (EFI) system. Replacing the old carburetor, the EFI system acts as the engine’s precision chef, electronically measuring and injecting the exact amount of fuel needed for perfect combustion.

While the EFI system is highly reliable, neglecting it can lead to rough idling, poor gas mileage, and costly repairs. The good news is that keeping your EFI system healthy is simple! Here is a beginner’s guide to proactive EFI maintenance.

1. The Golden Rule: Use Quality Fuel

The quality of the fuel you put in your tank is the single most important factor for EFI health.

- Avoid Contaminants: The fuel in your tank is the lifeblood of the EFI. Low-quality or contaminated fuel can introduce dirt, debris, and deposits that clog the fine spray nozzles of your fuel injectors.

- Stick to Reputable Stations: Always