New Product Development Course of action

Automotive style is the profession involved in the improvement of the look, and to some extent the ergonomics , of motor autos or more particularly road vehicles. The fifth step in the new solution development procedure includes a overview of the sales, costs and profit projections for the new product to come across out whether these aspects satisfy the company’s objectives. However, to raise the reliability of the test, a much more concrete and physical presentation of the item notion may be necessary. Some automobile businesses call for a higher visibility than other folks which is also crucial for the showroom design.

Automotive style is the profession involved in the improvement of the look, and to some extent the ergonomics , of motor autos or more particularly road vehicles. The fifth step in the new solution development procedure includes a overview of the sales, costs and profit projections for the new product to come across out whether these aspects satisfy the company’s objectives. However, to raise the reliability of the test, a much more concrete and physical presentation of the item notion may be necessary. Some automobile businesses call for a higher visibility than other folks which is also crucial for the showroom design.

The Stage-Gate approach defines the cross-functional and parallel activities that every stage need to engage in. Between the stages are gates which control the procedure and serve as go/kill checkpoints for the project as properly as supply good quality-manage of the course of action. Industry research can also …

New Product Development Course of action Read More

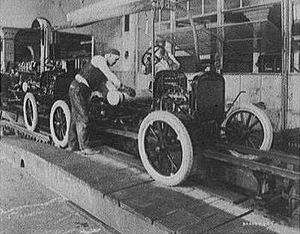

CELERIFERE the initially car absolutely free from animals knows as the 1st generation bicycle paved way for series of new discoveries major modern day cycles. History of the Assembly Line : A brief summary of the use of the assembly line in the meatpacking industry, and of its later presence in the auto market. In an assembly line, car assembly is split among a number of stations, all functioning simultaneously. Meat Packing : A brief discussion of factory workers and assembly lines in today’s meatpacking business. In the early days of automobile production, competitors for production line workers was fierce, and auto businesses offered – or were forced to offer you by worker’s unions – generous pay.

CELERIFERE the initially car absolutely free from animals knows as the 1st generation bicycle paved way for series of new discoveries major modern day cycles. History of the Assembly Line : A brief summary of the use of the assembly line in the meatpacking industry, and of its later presence in the auto market. In an assembly line, car assembly is split among a number of stations, all functioning simultaneously. Meat Packing : A brief discussion of factory workers and assembly lines in today’s meatpacking business. In the early days of automobile production, competitors for production line workers was fierce, and auto businesses offered – or were forced to offer you by worker’s unions – generous pay. An assembly line is a manufacturing method (most of the time called a progressive assembly) in which components (normally interchangeable parts ) are added as the semi-completed assembly moves from workstation to workstation exactly where the components are added in sequence till the final assembly is produced. The air pollution in assembly plant can result in lung carcinoma,asthma,skin allergy,infertility and air pollution can be decreased by making use of Low-VOC paints,great residence keeping,solvent management,utilizing PPE the worker have to put on helmets with visors operating in painting section,they can use the dress which is lint absolutely free as employed in basic motors paint section,masks have to be utilised for those who are working near by sections of painting shops.

An assembly line is a manufacturing method (most of the time called a progressive assembly) in which components (normally interchangeable parts ) are added as the semi-completed assembly moves from workstation to workstation exactly where the components are added in sequence till the final assembly is produced. The air pollution in assembly plant can result in lung carcinoma,asthma,skin allergy,infertility and air pollution can be decreased by making use of Low-VOC paints,great residence keeping,solvent management,utilizing PPE the worker have to put on helmets with visors operating in painting section,they can use the dress which is lint absolutely free as employed in basic motors paint section,masks have to be utilised for those who are working near by sections of painting shops. Paint is any liquid , liquefiable, or mastic composition that, soon after application to a substrate in a thin layer, converts to a solid film. At course of action block 412, a consumer industrial hygiene group reviews the solution data sheet information and performs at method block 416 all relevant emissions data. Individuals-associated data structure 375 interrelates with relevant method actions 364 such individuals-connected data as typical coaching plan, job title, and job descriptions. The method actions 364 incorporate the measures employed inside the course of action of a paint laboratory, or a resin manufacturing factory, or a paint manufacturing factory, or a car assembly plant.

Paint is any liquid , liquefiable, or mastic composition that, soon after application to a substrate in a thin layer, converts to a solid film. At course of action block 412, a consumer industrial hygiene group reviews the solution data sheet information and performs at method block 416 all relevant emissions data. Individuals-associated data structure 375 interrelates with relevant method actions 364 such individuals-connected data as typical coaching plan, job title, and job descriptions. The method actions 364 incorporate the measures employed inside the course of action of a paint laboratory, or a resin manufacturing factory, or a paint manufacturing factory, or a car assembly plant. The world’s 1st assembly line was developed at the Ford Motor Co. in 1913, creating this its centenary year. Even even though assembly lines existed prior, it was Ford who perfected the line and really created it a staple of the American auto business and the manufacturing sector. Steven Cherry: We’ve been speaking with historian David Nye, author of the new book America’s Assembly Line, about the past, present, and future of the assembly line. Noise – Auto assembly plants will be noisy,due to the functioning of machines and robots.

The world’s 1st assembly line was developed at the Ford Motor Co. in 1913, creating this its centenary year. Even even though assembly lines existed prior, it was Ford who perfected the line and really created it a staple of the American auto business and the manufacturing sector. Steven Cherry: We’ve been speaking with historian David Nye, author of the new book America’s Assembly Line, about the past, present, and future of the assembly line. Noise – Auto assembly plants will be noisy,due to the functioning of machines and robots.