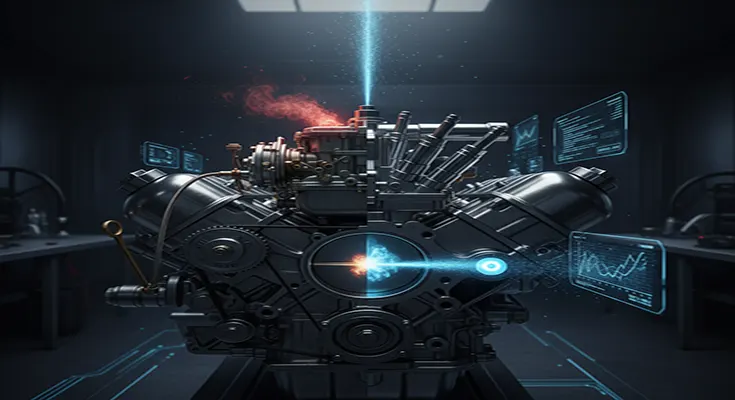

The ECU Revolution: Key Advantages of Electronic Fuel Injection (EFI) Over Carburetors

For over a century, the simple, mechanical carburetor was the undisputed champion of mixing air and fuel for internal combustion engines. However, starting in the 1980s, a technological revolution—driven by rising fuel prices, stricter environmental laws, and the dawn of computer control—swept across the automotive industry. The result was the near-universal adoption of the Electronic Fuel Injection (EFI) system.

While carburetors retain a nostalgic appeal for their simplicity in classic cars, the EFI system is unequivocally superior in virtually every measurable metric for modern vehicles. This superiority is rooted in one key difference: precision.

Here are the major advantages of Electronic Fuel Injection systems over carburetors.

1. Unmatched Fuel Efficiency and Economy

The greatest single advantage of EFI is its ability to precisely manage fuel consumption, which a mechanical carburetor simply cannot match.

- Optimized Air/Fuel Ratio: The heart of the EFI system is the Electronic Control Unit (ECU)