There are several different types of fuel systems in vehicles today. Those that are common include the Gravity fuel system and the Multi-point injectors. This article will talk about both types. In addition, you will learn about the Direct injection system and the Returnless fuel system. After reading this article, you will be well-equipped to make an informed choice regarding your car’s fuel system. Listed below are some of the benefits of each type.

Gravity fuel system

A gravity fuel system is a type of aircraft fuel system that relies on gravity to feed the aircraft’s engine. These systems are only practical if the fuel tanks are higher than the aircraft’s wings, and are therefore often found on high-wing aircraft. These systems must provide enough fuel flow for at least 150 percent of take-off fuel consumption, as well as throughout the certified flight envelope. Additionally, booster pumps are sometimes installed to supplement gravity fed fuel systems, and are generally used with carburetor or fuel injected engines.

A new type of gravity fuel system could be the answer to many of today’s problems in the automotive industry. It could provide a cost-effective alternative to green hydrogen and may also be useful alongside a hydrogen-electric hybrid system. This new system could also spur innovation in regenerative braking systems in consumer EVs. For example, the gravity fuel system in EV trucks could act as an Energy Vault, storing energy produced during braking and converting it back into electricity.

Multi-point injectors

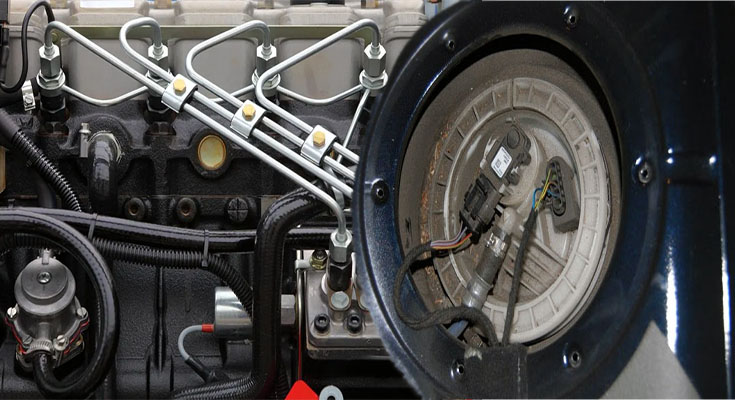

In an automobile, Multi-point injectors are used to provide a consistent amount of fuel to the combustion chamber. These devices are electromagnetically driven and connected to the fuel line. Because fuel is supplied under high pressure, a ramp is required to collect the fuel in the injector’s cavity. The injector’s margin allows for different nozzle actions, such as constant or multi-layer injection, depending on engine cycle requirements.

The multi-point fuel injection system contains a fuel pressure regulator, multiple individual injectors, and cylinders. Each individual injector sprays fuel into the intake manifold above the intake valves. Compared to other fuel injection methods, this method has fewer components and is easier to use. This fuel system is less complex than sequential Multi-Point Injection and is also more accurate. Multi-point systems also provide a better air-fuel ratio and prevent fuel condensation.

Direct injection system

A Direct Injection system is the most popular method of fuel injection for gasoline- powered vehicles. The main difference between Direct Injection and port injection is the amount of pressure applied to the injectors. In a port-injection system, the fuel is delivered to the injectors at high pressure, while in a Direct Injection system, the fuel is delivered at a lower pressure. This method is preferred over port-injection due to its superior cold starting and low-pressure capability. It also provides greater reliability and efficiency and is more flexible, with more sophisticated mechanical components.

In a direct injection system, the fuel is injected directly into the combustion chamber without having to be mixed with the air. This method of fuel delivery is most effective in petrol-powered engines, although it has been used successfully for diesel engines as well. Direct injection systems increase the efficiency of the engine and reduce emissions. During the early years of direct injection, the technology was not mature enough to be widely adopted by car manufacturers. Despite the advances in direct-injection technology, the system still has many drawbacks.

Returnless fuel system

Returnless fuel systems use a powertrain control module (PCM) to regulate the amount of fuel delivered to the engine. This PCM compensates for the decrease in fuel pressure by varying the voltage supply to the fuel pump. Ford systems increase the pump speed by pulse-width modulation to compensate for the loss of fuel pressure. The fuel rail is often contaminated with gunk and grit. The fuel pressure gauge is a critical tool for determining whether the fuel pressure sensor is out of calibration.

Another type of returnless fuel system uses electronic controls. The fuel pump and rail work together to distribute fuel to the engine. A pressure regulator detects the fuel pressure and controls the operating speed and duration of the fuel pump. As a result, the fuel temperature is regulated and the resulting vapors are lowered. With the fuel temperature lower than the vapor level, returnless fuel systems reduce emissions and improve fuel economy. These systems have proven to be an ideal solution for the new evaporative emissions regulations.