The new rotary engine is a welcome development after years of meh emissions and unstable durability. However, a new startup firm, Astron, has developed a 33-pound rotary engine that produces 162 horsepower. This is a far cry from the typical 840- pound turbocharged V8 diesel engine with 340hp and a power-to-weight ratio of 0.40hp/lb.

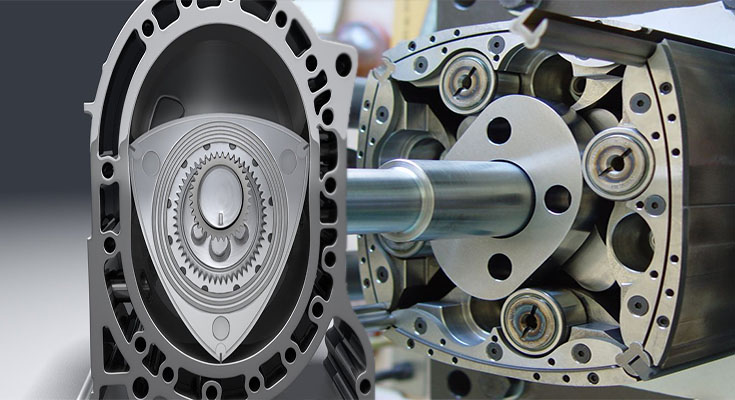

Szorenyi rotary engine design

The Szorenyi rotary engine is a simple, purely mechanical engine with one chamber, a rotor. It uses a mathematically defined stator. In the Szorenyi rotary engine, the rotor segments change from a square configuration to a rhombic one during rotation. This design achieves a volumetric efficiency of 100%. It can operate with a wide-open throttle without knocking. Its main features are centered around the combustion chamber and the pressure on the stator. Its internal structure features a direct contact power take-off crank mechanism.

REDA’s new engine design can also run on diesel fuel, with a pre-compression phase. Its design is aligned with the concept of the “one fuel” by the U.S. military. It is described in a SAE Technical Paper. The Szorenyi rotary engine is capable of running on gasoline, avgas, butane, hydrogen, and propane. Its well-separated inlet and exhaust ports allow for a variety of fuel types, including ethanol and biodiesel.

Mazda’s new rotary engine design

It is unclear whether Mazda will continue to produce the iconic rotary engine, which was last seen in the MX-5 in the late 1980s. While the company has stated that it will return with the MX-30 in 2022, rumors have swirled that the rotary is being shelved for the time being. In an effort to keep the engine relevant, Mazda is looking at several auto applications. The new engine will also be used as a range extender for electric vehicles.

The new rotary engine design features two major changes from its predecessors. The exhaust ports are now placed on the side of the engine housing, which eliminates the overlap in the exhaust port and improves intake resistance. The exhaust port also has a passage for the water jacket. The engineers also redesigned the rotor seals, which have two cut-off rings and a low-height apex.

Liquid Piston’s rotary engine design

With a weight of 1.5 kilograms, the LiquidPiston power plant is ideal for use in a variety of applications. This technology is also suitable for use in drones and hybrid vehicles, as well as in chainsaws. The new design also has the potential to reduce fuel consumption and improve range. Besides electric power, LiquidPiston is also planning to introduce its technology to the automotive and industrial markets.

In contrast to Wankel engines, LiquidPiston’s rotary engines feature an oval rotor that moves inside a triangular housing. While this may seem similar, the LiquidPiston design is characterized by its high power density and simplicity. The unit is roughly the size of a gaming PC. In addition to rotary engines, the new LiquidPiston generator is capable of generating electricity.

Di Pietro’s rotary engine design

A key feature of the Di Pietro rotary engine design is its use of pneumatic power. The high pressure air from the engine’s basement can be run to several ports to run pneumatic tools. The directional valve is also an important part of the control system. When the pressure of air is too low, the engine fails to rotate. Consequently, the pressure in the air channels must be adjusted. Angelo Di Pietro used CFD software to determine the distribution of pressure values in the inlet and outlet channels of the engine. Then, he studied the engine’s operation for selected stages.

Angelo Di Pietro’s rotary engine design is a revolutionary engine powered by compressed air. Because the engine doesn’t produce exhaust or noise, it’s less noisy than a conventional gasoline engine. Furthermore, the engine costs less than one- sixth the fuel of a conventional small diesel engine. Angelo Di Pietro’s rotary engine design is protected by worldwide patents and has attracted serious interest from various companies worldwide. The engine is light and compact. It weighs only 13 kilograms, compared to a conventional air engine that can weigh more than 90 kilograms.