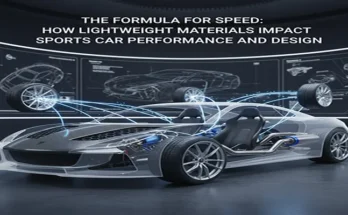

The pursuit of speed, stability, and efficiency has made aerodynamics a cornerstone of modern sports car design. No longer just an afterthought, the way air flows around and through a vehicle is meticulously engineered to achieve maximum performance, transforming a static piece of sculpture into a dynamic, ground-hugging machine.

At its heart, automotive aerodynamics is the controlled management of two primary forces: drag and downforce.

Key Aerodynamic Principles

1. Minimizing Drag (Air Resistance)

Drag () is the air resistance that opposes a car’s motion. As speed increases, the frictional force of aerodynamic drag rises significantly, demanding more engine power to maintain or increase velocity. The goal of modern design is to achieve a low drag coefficient ().

- Streamlining the Body: This is the most fundamental principle. Sports cars employ smooth curves, tapered rears, and low profiles to ensure air flows over the body with minimal separation. Early designs, like those inspired by aviation, established the importance of the teardrop shape.

- Controlling the Wake: The area of turbulent, low-pressure air behind the car (the wake) contributes significantly to drag. Designers use elements like a clean, tapered rear end and strategically placed spoilers to manage this turbulence, effectively “closing” the wake to reduce the pressure differential that pulls the car backward.

- Integrating Components: Even seemingly minor parts like door handles, mirrors, and body panel gaps are often recessed or designed to reduce their contribution to drag. The flat or sculpted underbody is also crucial for smooth, high-speed airflow.

2. Maximizing Downforce (Ground Adhesion)

While drag slows the car, downforce () is the vertical force that pushes the vehicle’s tires onto the road, enhancing grip and improving stability—especially in corners. Unlike the weight of the car, which is constant, downforce increases with the square of speed.

- Wings and Spoilers: The most visible downforce generators. A rear wing works like an inverted aircraft wing, creating a high-pressure zone above it and a low-pressure zone beneath, pushing the rear wheels down. A spoiler typically sits flush with the body and is designed to disrupt the lift-creating airflow over the car’s top surface.

- The Diffuser: Located at the rear underside, the diffuser is arguably the most effective component for generating downforce with minimal drag penalty. It works by creating an expansion volume for the fast-moving air exiting from under the car, which accelerates the airflow beneath the vehicle. According to Bernoulli’s principle, faster air equals lower pressure, creating a vacuum effect that sucks the car to the ground. This is a key principle of ground effect aerodynamics.

- Front Splitters and Air Dams: These front-end elements manage airflow at the very beginning of the car. They prevent excessive air from flowing underneath the chassis (where it could cause lift) and direct high-pressure air streams up and over the front of the car, contributing to front-axle downforce and balance.

Modern Innovations: Active Aerodynamics

The latest sports cars move beyond static design with active aerodynamic systems that dynamically adapt to driving conditions, providing the best of both worlds: low drag for straight-line speed and high downforce for cornering stability.

- Adjustable Wings and Spoilers: These components automatically change their angle of attack or height based on vehicle speed, braking, and steering input. For instance, at maximum speed on a straight, a wing may retract or flatten to reduce drag (like Formula 1’s DRS system). During hard braking or cornering, it deploys instantly to maximize downforce and stability.

- Movable Underbody Elements: Active elements like adjustable front splitter flaps or movable venturi tunnels can open or close air channels underneath the car to quickly modulate the pressure distribution, optimizing the downforce balance between the front and rear axles in real-time.

- Air Brakes: Some rear wings can deploy almost vertically during heavy braking to act as a massive air brake, significantly increasing drag to aid in deceleration and shifting the aerodynamic balance reward to improve stability.

The Design Process: Technology at the Forefront

Achieving the perfect balance between drag and downforce is an iterative, complex process driven by cutting-edge technology:

- Computational Fluid Dynamics (CFD): This is a computer-based simulation tool that models how air flows over every surface of a virtual car. CFD allows engineers to test hundreds of design iterations quickly and cost-effectively, analyzing air pressure, velocity, and turbulence to optimize every millimeter of the design before building a physical model.

- Wind Tunnel Testing: Physical wind tunnels remain the gold standard for final validation. In these controlled environments, full-scale or scaled models are subjected to real airflow, and sensors measure the actual drag and downforce forces. Advanced tunnels often feature a rolling road—a moving floor that simulates the car’s movement relative to the ground—to ensure the underbody airflow is accurately represented.

In conclusion, modern sports car design is an elegant dance between styling and science. By applying the principles of aerodynamics and leveraging active technologies and advanced simulation tools, manufacturers ensure that their vehicles are not just fast, but also stable, efficient, and exhilarating to drive at any speed.