Tips on How to Buy a New Or Used Auto and Get a Good Deal

Shopping for something as vital and expensive as an automobile deserves a substantial amount of time and research to be finished on the buyers half. Realizing what you want and what you desire can typically be 2 totally different things. It’s your decision on if you should get a sports utility vehicle where you will get a decrease in gas mileage or a hybrid automobile. Already you’ll be able to see how buying a car could be a delicate decision, but this shouldn’t prevent you from getting a great deal on your next vehicle.

Getting a great deal can seem troublesome with all the tales of aggressive salesmen attempting to add on pointless extras and the battle of intellect relating to negotiating the price. Some new buyers might not necessarily know all the small print and what to search for when shopping for an automobile so what follows is an …

Tips on How to Buy a New Or Used Auto and Get a Good Deal Read More

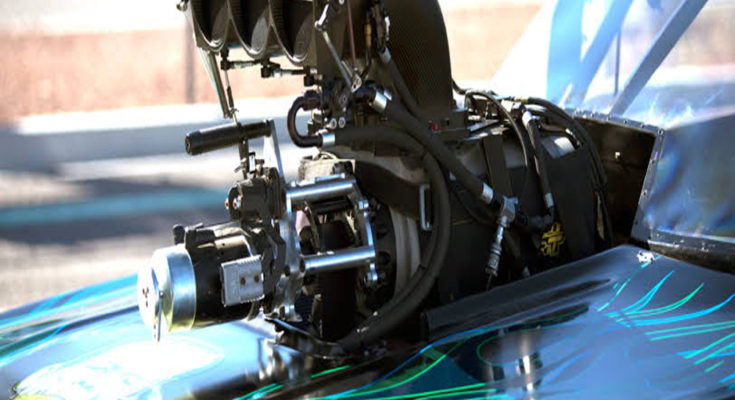

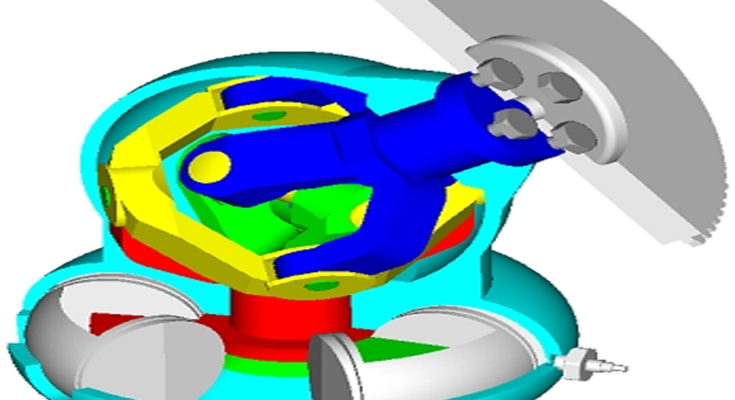

Historically, the opposed-piston engine set combined records for fuel efficiency and energy density that have however to be met by any other engine form. Then, the port is closed by the skirt of piston 44 as the crankshaft moves 270 degrees to best dead center and thence, therepast 90 degrees. An opoc® engine has no cylinder heads, valvetrain components, or other mechanicals connected with standard engines. FIGURE 1 is a side elevational view of a single cylinder opposed piston engine constructed according to the principles of the invention and arranged for operation with steam or compressed air.

Historically, the opposed-piston engine set combined records for fuel efficiency and energy density that have however to be met by any other engine form. Then, the port is closed by the skirt of piston 44 as the crankshaft moves 270 degrees to best dead center and thence, therepast 90 degrees. An opoc® engine has no cylinder heads, valvetrain components, or other mechanicals connected with standard engines. FIGURE 1 is a side elevational view of a single cylinder opposed piston engine constructed according to the principles of the invention and arranged for operation with steam or compressed air.