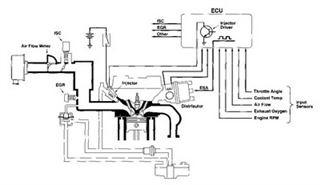

EFI Controller

In addition to its key purpose of speed manage, this EFI controller series offers features which are valuable for engine efficiency, such as optimised fuel efficiency, elevated engine energy, and fewer environmentally harmful emissions. It is only with the advent of multi-point fuel injection specific engine configurations such as inline 5 cylinder gasoline engines have turn into additional feasible for mass production, as conventional carburetor arrangement with single or twin carburetors could not offer even fuel distribution among cylinders, unless a far more complex individual carburetor per cylinder is applied.

In addition to its key purpose of speed manage, this EFI controller series offers features which are valuable for engine efficiency, such as optimised fuel efficiency, elevated engine energy, and fewer environmentally harmful emissions. It is only with the advent of multi-point fuel injection specific engine configurations such as inline 5 cylinder gasoline engines have turn into additional feasible for mass production, as conventional carburetor arrangement with single or twin carburetors could not offer even fuel distribution among cylinders, unless a far more complex individual carburetor per cylinder is applied.

The Bendix technique is a direct descendant of the stress carburetor Nonetheless, as an alternative of possessing a discharge valve in the barrel, it makes use of a flow divider mounted on top rated of the engine, which controls the discharge rate and evenly distributes the fuel to stainless steel injection lines to the intake ports of each cylinder.

Benefits of fuel injection consist of smoother and far more constant transient throttle response, such as for the duration of fast throttle transitions, simpler cold starting, far more correct adjustment to account for extremes of ambient temperatures and adjustments in air stress, much more steady idling, decreased maintenance demands, and much better fuel efficiency.

Earlier systems, relying on simpler injectors, typically injected into a sub-chamber shaped to swirl the compressed air and enhance combustion this was recognized as indirect injection On the other hand, this was much less effective than the now typical direct injection in which initiation of combustion takes spot in a depression (frequently toroidal ) in the crown of the piston.

Based on the method design, the timing of when injector opens is either relative each person cylinder (for a sequential fuel injection program), or injectors for several cylinders might be signalled to open at the exact same …

EFI Controller Read More

In developed and building nations considerable emphasis is becoming laid on the minimization of pollutants from internal combustion engines. Fuel injection was phased in through the latter 1970s and 80s at an accelerating price, with the German, French, and U.S. markets major and the UK and Commonwealth markets lagging somewhat. Made in China 2025, released by China in May possibly 2015, stated that the Government will press ahead with the application of diesel engines in passenger autos.

In developed and building nations considerable emphasis is becoming laid on the minimization of pollutants from internal combustion engines. Fuel injection was phased in through the latter 1970s and 80s at an accelerating price, with the German, French, and U.S. markets major and the UK and Commonwealth markets lagging somewhat. Made in China 2025, released by China in May possibly 2015, stated that the Government will press ahead with the application of diesel engines in passenger autos. Voltage drops happen when current and voltage meet some type of resistance. Although a easy carburetor technique is more affordable to manufacture than a fuel injection method, the additional complex carburetor systems installed on a lot of engines in the 1970s were considerably far more costly than the earlier easy carburetors. Whilst the other subgroup covers alternator and ignition program, timing belt, intake manifold + exhaust manifold, water pump + water hose, rocker arm + camshaft, cylinder head + valves, Oil pan + oil pump, piston + conrod, crankshaft + cylinder block. In piston aircraft engines, continuous-flow fuel injection is the most frequent sort.

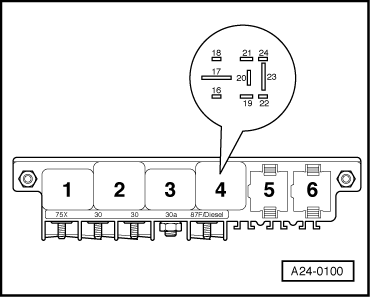

Voltage drops happen when current and voltage meet some type of resistance. Although a easy carburetor technique is more affordable to manufacture than a fuel injection method, the additional complex carburetor systems installed on a lot of engines in the 1970s were considerably far more costly than the earlier easy carburetors. Whilst the other subgroup covers alternator and ignition program, timing belt, intake manifold + exhaust manifold, water pump + water hose, rocker arm + camshaft, cylinder head + valves, Oil pan + oil pump, piston + conrod, crankshaft + cylinder block. In piston aircraft engines, continuous-flow fuel injection is the most frequent sort. Electronic fuel injections are a method which enables fuel into a central combustion engine, electronic fuel injection systems break up the fuel by powerfully pushing it through a tiny syringe beneath a extremely high stress. Porsche continued working with this method on its racing vehicles into the late seventies and early eighties. With the implementation of the national IV emission common, as the most appropriate technology roadmap, prevalent rail system for diesel engines witnessed speedy improvement. Engine mechanical describes installation and removal of these components: drive belt tension, auto tensioner, ignition timing belt, idle speed and mixture, compression pressure, manifold vacuum, lash adjuster, crankshaft pulley, camshaft and valve stem seal, oil pan, crankshaft oil sea, timing belt and engine assy. Wide functionality and hassle-free quantity of I/ for optimal engine operation and monitoring.

Electronic fuel injections are a method which enables fuel into a central combustion engine, electronic fuel injection systems break up the fuel by powerfully pushing it through a tiny syringe beneath a extremely high stress. Porsche continued working with this method on its racing vehicles into the late seventies and early eighties. With the implementation of the national IV emission common, as the most appropriate technology roadmap, prevalent rail system for diesel engines witnessed speedy improvement. Engine mechanical describes installation and removal of these components: drive belt tension, auto tensioner, ignition timing belt, idle speed and mixture, compression pressure, manifold vacuum, lash adjuster, crankshaft pulley, camshaft and valve stem seal, oil pan, crankshaft oil sea, timing belt and engine assy. Wide functionality and hassle-free quantity of I/ for optimal engine operation and monitoring. It’s the last thing you’d believe about in the summer, but the industry can thank German supplier Robert Bosch for the technologies that changed the way individuals start off their automobiles. The pressure drop across the restrictions in the control unit controls the quantity of fuel flow, so that fuel flow is straight proportional to the pressure at the flow divider. Most diesel engines (with the exception of some tractors and scale model engines ) have fuel injected into the combustion chamber. In a continuous injection technique, fuel flows at all occasions from the fuel injectors, but at a variable flow price. Fuel rail connected to the injectors that are mounted just above the intake manifold on a 4-cylinder engine.

It’s the last thing you’d believe about in the summer, but the industry can thank German supplier Robert Bosch for the technologies that changed the way individuals start off their automobiles. The pressure drop across the restrictions in the control unit controls the quantity of fuel flow, so that fuel flow is straight proportional to the pressure at the flow divider. Most diesel engines (with the exception of some tractors and scale model engines ) have fuel injected into the combustion chamber. In a continuous injection technique, fuel flows at all occasions from the fuel injectors, but at a variable flow price. Fuel rail connected to the injectors that are mounted just above the intake manifold on a 4-cylinder engine.