Assembly Line Manufacturing From Ford

The German automobile organization is laying off the machine staff and hiring folks to assemble its customized luxury cars. So it tends see exactly where, from the Nazi viewpoint, you may say the assembly line is an perfect technology for exterminating men and women, but in the U.S. they are embracing it for a complete nother set of factors. So there is a group who are nicely paid, have excellent jobs in the auto sector, but there was a time when it was the good location for an average Joe, or an average Jill, I suppose, an average particular person without having any excellent education or a lot of expertise, to go and get a job that had high spend and very good benefits.

The German automobile organization is laying off the machine staff and hiring folks to assemble its customized luxury cars. So it tends see exactly where, from the Nazi viewpoint, you may say the assembly line is an perfect technology for exterminating men and women, but in the U.S. they are embracing it for a complete nother set of factors. So there is a group who are nicely paid, have excellent jobs in the auto sector, but there was a time when it was the good location for an average Joe, or an average Jill, I suppose, an average particular person without having any excellent education or a lot of expertise, to go and get a job that had high spend and very good benefits.

Right after finishing its operate on the initially vehicle, the engine installation crew can begin operating on the second car. This happens almost 100 instances per …

Assembly Line Manufacturing From Ford Read More

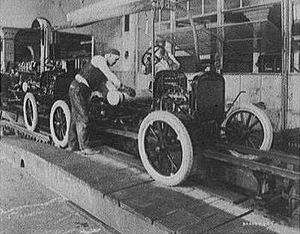

An assembly line is a line of factory workers and gear that produce a solution as it moves consecutively from station to station on the line till completed. Although Olds’ assembly line for cars might have been the first, Henry Ford’s assembly line was constructed on basically the exact same thought and was far much more efficient. Panhard-Levassor made automobiles with a pedal-operated clutch, a chain transmission major to a alter-speed gearbox, and a front radiator. It was not until the 1800’s that the assembly line became related to what it is today. The idea of employing an assembly line for automobiles was instituted by Ransom Olds in 1901. The passage of years has brought numerous variations in assembly line methodologies.

An assembly line is a line of factory workers and gear that produce a solution as it moves consecutively from station to station on the line till completed. Although Olds’ assembly line for cars might have been the first, Henry Ford’s assembly line was constructed on basically the exact same thought and was far much more efficient. Panhard-Levassor made automobiles with a pedal-operated clutch, a chain transmission major to a alter-speed gearbox, and a front radiator. It was not until the 1800’s that the assembly line became related to what it is today. The idea of employing an assembly line for automobiles was instituted by Ransom Olds in 1901. The passage of years has brought numerous variations in assembly line methodologies. Bucking modern day manufacturing trends, Mercedes-Benz has been forced to trade in some of its assembly line robots for far more capable humans. 1 of the last stops on the car assembly line is named final assembly This department puts gasoline in the vehicle as properly as checks the car for any missing elements. But it is, in a sense, a entire new way of pondering about what the assembly line ought to be in a position to do, to, in a sense, go back to the ultimate origins, the slaughterhouse assembly lines that took issues apart.

Bucking modern day manufacturing trends, Mercedes-Benz has been forced to trade in some of its assembly line robots for far more capable humans. 1 of the last stops on the car assembly line is named final assembly This department puts gasoline in the vehicle as properly as checks the car for any missing elements. But it is, in a sense, a entire new way of pondering about what the assembly line ought to be in a position to do, to, in a sense, go back to the ultimate origins, the slaughterhouse assembly lines that took issues apart. CELERIFERE the initially car absolutely free from animals knows as the 1st generation bicycle paved way for series of new discoveries major modern day cycles. History of the Assembly Line : A brief summary of the use of the assembly line in the meatpacking industry, and of its later presence in the auto market. In an assembly line, car assembly is split among a number of stations, all functioning simultaneously. Meat Packing : A brief discussion of factory workers and assembly lines in today’s meatpacking business. In the early days of automobile production, competitors for production line workers was fierce, and auto businesses offered – or were forced to offer you by worker’s unions – generous pay.

CELERIFERE the initially car absolutely free from animals knows as the 1st generation bicycle paved way for series of new discoveries major modern day cycles. History of the Assembly Line : A brief summary of the use of the assembly line in the meatpacking industry, and of its later presence in the auto market. In an assembly line, car assembly is split among a number of stations, all functioning simultaneously. Meat Packing : A brief discussion of factory workers and assembly lines in today’s meatpacking business. In the early days of automobile production, competitors for production line workers was fierce, and auto businesses offered – or were forced to offer you by worker’s unions – generous pay. The world’s 1st assembly line was developed at the Ford Motor Co. in 1913, creating this its centenary year. Even even though assembly lines existed prior, it was Ford who perfected the line and really created it a staple of the American auto business and the manufacturing sector. Steven Cherry: We’ve been speaking with historian David Nye, author of the new book America’s Assembly Line, about the past, present, and future of the assembly line. Noise – Auto assembly plants will be noisy,due to the functioning of machines and robots.

The world’s 1st assembly line was developed at the Ford Motor Co. in 1913, creating this its centenary year. Even even though assembly lines existed prior, it was Ford who perfected the line and really created it a staple of the American auto business and the manufacturing sector. Steven Cherry: We’ve been speaking with historian David Nye, author of the new book America’s Assembly Line, about the past, present, and future of the assembly line. Noise – Auto assembly plants will be noisy,due to the functioning of machines and robots.