Tobacco Growing And Curing At Residence.

Frigmaires incorporated in 1961 as a partnership firm mainly producers of course of action plants and machinery essential by the Chemical, Paint, Inks Pharmaceuticals, Minerals, Meals and related Industries. If choice block 448 has determined that the problem has previously occurred, then the customer at approach block 464 identifies the stored corrective actions taken with respect to that similar difficulty. The primary input components described by the paint application data structure 156 are the paint components that are the products of the paint manufacturing data structure 152. Course of action handle data structure template 353 interrelates paint-connected data with one particular or additional relevant approach measures of the paint spraying program.

Frigmaires incorporated in 1961 as a partnership firm mainly producers of course of action plants and machinery essential by the Chemical, Paint, Inks Pharmaceuticals, Minerals, Meals and related Industries. If choice block 448 has determined that the problem has previously occurred, then the customer at approach block 464 identifies the stored corrective actions taken with respect to that similar difficulty. The primary input components described by the paint application data structure 156 are the paint components that are the products of the paint manufacturing data structure 152. Course of action handle data structure template 353 interrelates paint-connected data with one particular or additional relevant approach measures of the paint spraying program.

Information sources 124 contain information being acquired from one or much more paint laboratories 132, 1 or a lot more paint manufacturing factories 136, and one particular or additional car assembly plants 140. The primary output item described by the resin manufacturing information structure 148 are the resins that are produced from the chemical substances. Data acquisition regarding the manufacturing of the paint is performed by the paint manufacturing process handle block 88.

At process block 400, a user, such as a client, from a remote web-site obtains particular technical data with regards to the paint spraying technique. Safety data is positioned preferably in technical database 172 for making sure that only authorized users (whoever and wherever they may possibly be) can view the portions of the data contained within the computerized virtual paint manufacturing and application technique 120 that they are authorized to view.

Inside that capacity, the PROSIM device 246 permits paint material from a paint manufacturing plant to be analyzed to make certain compliance with predefined quality requirements. For example, a variety of painting factor values that result in reasonably low R-squared values for the paint …

Tobacco Growing And Curing At Residence. Read More

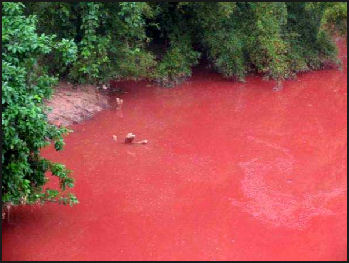

Bacterial contamination can trigger colour and odour problems with water primarily based paint merchandise so a rapidly and trustworthy contamination detection device is highly desirable to supply early warning of contamination in paint before reaching the client mainly because the economic implications of a spoilt batch are incredibly higher. Likewise, a personal computer containing the paint application information structure 156 is situated at a car assembly plant 140. Security data 277 about how an entity that is external to the computerized virtual paint manufacturing and application program 120 may possibly access the data is also contained in the technical database 172. For a more complete understanding of the paint simulation personal computer system 248, please refer to U.S. Pat.

Bacterial contamination can trigger colour and odour problems with water primarily based paint merchandise so a rapidly and trustworthy contamination detection device is highly desirable to supply early warning of contamination in paint before reaching the client mainly because the economic implications of a spoilt batch are incredibly higher. Likewise, a personal computer containing the paint application information structure 156 is situated at a car assembly plant 140. Security data 277 about how an entity that is external to the computerized virtual paint manufacturing and application program 120 may possibly access the data is also contained in the technical database 172. For a more complete understanding of the paint simulation personal computer system 248, please refer to U.S. Pat. PPG Asian Paints has made a substantial distinction in the paints sector with its state-of-the-art OEM automotive coatings manufacturing facility in the SIPCOT Industrial Park, Sriperumbudur, Tamil Nadu. Data structures 148, 152 and 156 and computers 160 are collectively termed the method manage coordinator 162. Solvent & Aqueous coating Lamination Working with an exclusive procedure, this process answers a growing want in agriculture and automotive equipment manufacturing. The paint supplies and their properties are described within the components module of the paint application information structure 156.

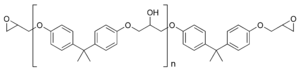

PPG Asian Paints has made a substantial distinction in the paints sector with its state-of-the-art OEM automotive coatings manufacturing facility in the SIPCOT Industrial Park, Sriperumbudur, Tamil Nadu. Data structures 148, 152 and 156 and computers 160 are collectively termed the method manage coordinator 162. Solvent & Aqueous coating Lamination Working with an exclusive procedure, this process answers a growing want in agriculture and automotive equipment manufacturing. The paint supplies and their properties are described within the components module of the paint application information structure 156. Paint consists of binders, pigments and fillers, solvents or water, and of so-referred to as additives. A plurality of data displays connected to mentioned paint procedure manage information structure for remotely getting and viewing said interrelated paint procedure handle information. In order to get item information sheets, a consumer invokes method block 404 by preferably clicking on an icon on the screen of the data location remote site for a certain paint-related product.

Paint consists of binders, pigments and fillers, solvents or water, and of so-referred to as additives. A plurality of data displays connected to mentioned paint procedure manage information structure for remotely getting and viewing said interrelated paint procedure handle information. In order to get item information sheets, a consumer invokes method block 404 by preferably clicking on an icon on the screen of the data location remote site for a certain paint-related product.